Immersion heater

Product Description

Sinton immersion heaters are recognized for their superior quality and efficiency in heating applications. These heaters are designed to be directly immersed in liquids, providing fast and efficient heat transfer. The product range includes flanged heaters, screw plug heaters, over-the-side heaters, and circulation heaters, catering to a wide range of industrial applications. Manufactured with robust materials, these heaters ensure durability and long service life, even in the most demanding environments.

Immersion Heater Working Principle

The working principle of flange immersion heaters is based on resistance heating.When an electric current passes through the heating element, it generates heat and then transfers it to the medium.This heating process increases the temperature of the medium to ensure that it reaches the level required for a particular application.

Immersion Heater Specification

Applications

Sinton immersion heaters are versatile and can be used across various industries for numerous applications, including:

l Chemical processing for maintaining precise temperature controls.

l Oil and gas industries for heating fluids and gases in tanks or pipelines.

l Food and beverage industry for pasteurization and other heat treatment processes.

l Pharmaceutical manufacturing for controlled heating in the production of medicines.

l Water treatment plants for heating and maintaining temperature levels.

Customised Options

Understanding diverse industrial needs, Sinton offers custom-engineered solutions to match specific requirements. Options include:

l Different wattage and voltage configurations to match power supply constraints.

l Various materials such as stainless steel, titanium, or Incoloy for corrosion resistance in different environments.

l Integration of thermostats, thermocouples, and digital controls for precise temperature management.

l Custom sizes and shapes to fit unique tank or vessel configurations.

Features and Benefits

Sinton immersion heaters come with a range of features and benefits, such as:

l High energy efficiency, reducing operational costs.

l Even heat distribution for consistent process heating.

l Easy installation and maintenance, minimizing downtime.

l Robust construction for long-term reliability in industrial settings.

l Compliance with safety standards and certifications, ensuring a safe working environment

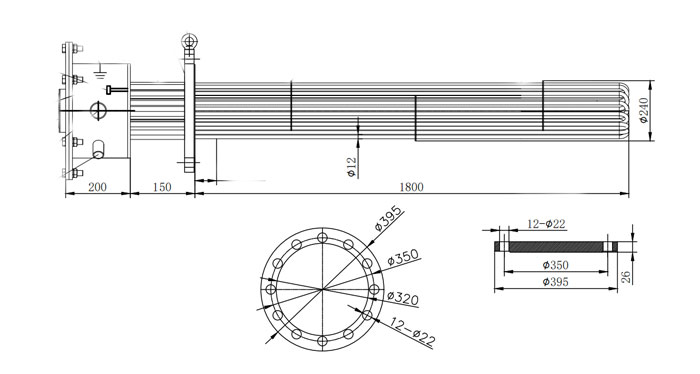

Technical specifications

The technical specifications of the flange immersion heater include parameters such as rated power, voltage, heating capacity and size.The rated power determines the heat generated by the heater, and it should be selected according to the specific heating requirements of the heated medium.Voltage compatibility is also an important consideration to ensure correct electrical connections.

Installation and use instructions

When installing flange heaters, the manufacturer's guidelines and safety precautions must be followed.The heater should be properly installed on the flange using bolts or other fastening methods.Ensure good electrical connections and proper insulation to prevent electric shock or short circuit.

During operation, the power supply of the flange heater should be controlled to adjust the heating intensity. A temperature sensor or controller can be used to monitor and maintain the desired temperature of the medium. It is important to avoid overheating or overheating to ensure optimal performance and safety.

SINTON ELECTRIC CO.,LTD.

Mobile: 0086-18556018866

Add : No.886, Yandu Road, Yandu District, Yancheng City, Jiangsu Province, China

https://www.jsxingtai.com/

Email: info@jsxingtai.com.cn